Sistemụ nhicha CIP zuru oke maka Tomato Tapawa Production Line

- Ọnọdụ:

- Ọhụrụ

- Ebe amụrụ:

- Shanghai, China

- Aha ika:

- JP

- Nọmba nlereanya:

- JC-CIP002

- Ụdị:

- ihe nchacha

- Voltaji:

- 380V/50HZ

- Ike:

- 2,2kw

- Arọ:

- 500 n'arọ

- Akụkụ (L*W*H):

- 1100*265*920mm

- Asambodo:

- CE/ISO9001

- Akwụkwọ ikike:

- Otu afọ

- Enyere ọrụ ire ere mgbe a gachara:

- Ndị injinia dị maka igwe ọrụ na mba ofesi

- Aha ngwaahịa:

- Sistemụ nhicha cip akpaaka

- Ngwa:

- Ụdị

- Ọrụ:

- Ịsacha Sterilizing

- Ihe:

- 304 igwe anaghị agba nchara

- Ojiji:

- Ojiji ụlọ ọrụ mmepụta ihe

- Njirimara:

- Dị mma

- Akụrụngwa:

- Igwe anaghị agba nchara

- Ihe:

- Igwe eji eji mkpụrụ osisi akpaaka

- Aha:

- Igwe nhicha CIP

- Nha tankị:

- 100-1000L

- Ikike inye:

- Usoro ihicha cip 5 kwa ọnwa

- Nkọwa nkwakọ ngwaahịa

- 1.Stable osisi ngwugwu na-echebe igwe site na iku na mmebi.Ihe nkiri plastik 2.Weund na-eme ka igwe ghara ịdị na mmiri na corrosion.

- Port

- Shanghai

- Etiti oge:

- ihe dị ka ụbọchị 30 mgbe ịnatachara n'ihu

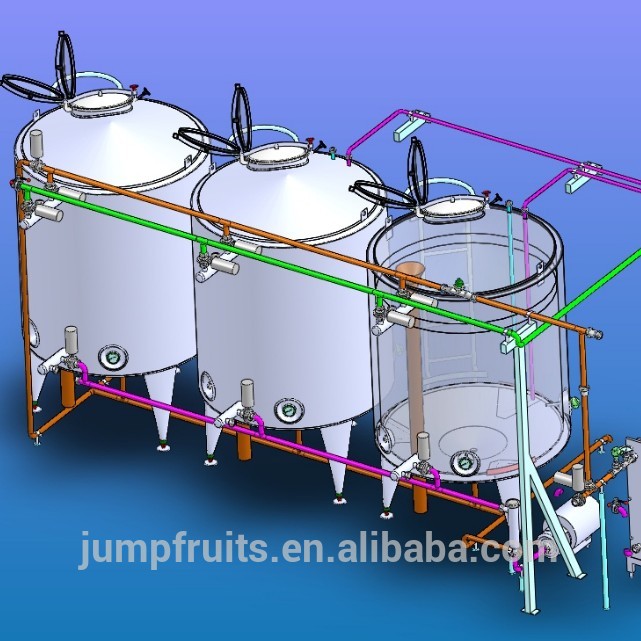

Sistemụ nhicha CIP akpaaka

Akpaaka CIP ihicha usoro maka mmiri ara ehi ngwaahịa, breweries, ihe ọṅụṅụ na izugbe nri osisi na ihe ọkpọkọ akụrụngwa na-ebe ihicha.Isi ihe: SUS304 na 316L, akụrụngwa sitere na tank alkali, tank acid, tank mmiri ọkụ, ụdị ọ bụla nke ọkpọkọ na valvụ pneumatic, ndị na-ebugharị nrụgide, mita conductivity, nguzogide platinum na usoro njikwa, wdg, iji mgbapụta centrifugal. Na-ebufe mmiri mmiri ihicha mmanye na-ekesa n'ime ọkpọkọ na akụrụngwa iji nweta nzube nke ihicha.Ya mere, ọ dịghị mkpa ịkwasa ngwá ọrụ pipeline, nke nwere ike imeziwanye ojiji akụrụngwa ma belata ọrụ onye ọrụ.A ghaghị ijikọta ihe eji eme ihe a kapịrị ọnụ na akụrụngwa na nhazi ọkpọkọ nke ụlọ ọrụ onye ọrụ na isi nhicha.

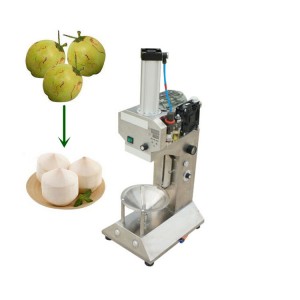

Igwe mbuli ịwụ

1. ezigbo ịwụ Ọdịdị megide clamping mkpụrụ osisi, adabara tomato, strawberry, apụl, ube, aprịkọt, wdg.

2. na-agba ọsọ nke ọma na obere mkpọtụ, na-agbanwe ọsọ site na transducer.

3. anticorrosive bearings, abụọ n'akụkụ akara.

Igwe na-afụ ikuku & ịsa ahụ

1 A na-eji saa tomato ọhụrụ, strawberry, mango, wdg.

2 Pụrụ iche imewe nke sọọfụ na bubbling iji hụ na a site ihicha na ibelata mmebi nke mkpụrụ osisi ahụ.

3 Kwesịrị ekwesị maka ọtụtụ ụdị mkpụrụ osisi ma ọ bụ akwụkwọ nri, dị ka tomato, strawberry, apple, mango, wdg.

Nchacha, ịhịa aka n'ahụ & Nnụcha Monobloc (Pulper)

1. The unit nwere ike bee, pulp na nụchaa mkpụrụ ọnụ.

2. Aperture nke ihuenyo strainer nwere ike gbanwee (mgbanwe) dabere na ihe ndị ahịa chọrọ.

3. Incorporated Italian technology, elu àgwà igwe anaghị agba nchara ihe na kọntaktị na mkpụrụ osisi.

Belt press extract

1. A na-eji ya eme ihe n'iwepụta na ịkpọ nkụ nke ọtụtụ ụdị acinus, mkpụrụ osisi pip, na akwụkwọ nri.

2. unit ahụ nakweere nkà na ụzụ dị elu, nnukwu pịa na arụmọrụ dị elu, ogo dị elu nke akpaka, dị mfe iji rụọ ọrụ na ịnọgide na-enwe.

3. mmịpụta ọnụego nwere ike nweta 75-85% (dabere na akụrụngwa)

4. obere ego na nnukwu arụmọrụ

Igwe ọkụ ọkụ

1. Ka inactivate enzyme na-echebe agba nke mado.

2. Nchekwa okpomọkụ na-apụ apụ na-agbanwe agbanwe.

3. Ọdịdị Multi-tubular na mkpuchi njedebe

4. Ọ bụrụ na mmetụta nke preheat na emenyụ enzyme dara ma ọ bụ na-ezughị, ngwaahịa eruba laghachi tube ọzọ na-akpaghị aka.

Evaporator

1. Ndị na-agbanwe agbanwe na ndị na-achịkwa kpọmkwem kọntaktị okpomọkụ ọgwụgwọ nkeji.

2. Oge obibi kacha dị mkpirikpi, ọnụnọ nke ihe nkiri dị mkpa n'ogologo dum nke tubes na-ebelata nkwụsị na oge obibi.

3. Nhazi pụrụ iche nke usoro nkesa mmiri mmiri iji hụ na mkpuchi tube ziri ezi.Nri na-abanye n'elu calandria ebe onye nkesa na-eme ka e guzobe ihe nkiri n'ime ime tube ọ bụla.

4. Mmiri na-asọ asọ na-ejikọta na mmiri mmiri na mmiri na-adọkpụ na-eme ka nnyefe ọkụ dịkwuo mma.A na-ekewa vepo na mmiri mmiri fọdụrụ na nkewa nke cyclone.

5. Nhazi nke ọma nke separators.

6. Usoro mmetụta otutu na-enye akụ na ụba uzuoku.

Ọkụ na tube sterilizer

1. The united bụ nke ngwaahịa na-enweta tank, superheated mmiri tank, nfuli, ngwaahịa dual filter, tubular superheated mmiri n'ịwa usoro, tube na tube okpomọkụ Exchanger, PLC akara usoro, Control kabinet, uzuoku ntinye usoro, valves na sensọ, wdg.

2. Incorporated Italian technology na kwekọrọ na Euro-ọkọlọtọ

3. Nnukwu ebe mgbanwe okpomọkụ, obere ike oriri na nlekọta dị mfe

4. Were mirror ịgbado ọkụ tech na-eji ire ụtọ anwụrụ nkwonkwo

5. Backtrack akpaaka ma ọ bụrụ na ezughi oke igba ogwu

6. CIP na auto SIP dị ọnụ na aseptic filler

7. Liquid larịị na temp akara na ozugbo