Tomato tapawa mmepụta akara na ike nke 1000 tọn kwa ụbọchị

- Ọnọdụ:

-

Ọhụrụ

- Ebe Mmalite:

-

Shanghai, China

- Brand aha:

-

OEM

- Nọmba nlereanya:

-

JUMP-FQJL050

- Ụdị:

-

tomato mmepụta ketchup

- Voltaji:

-

220V / 380V

- Ike:

-

120 kw

- Arọ:

-

100 IRI

- Dimension (L * W * H):

-

2100 * 1460 * 1590mm

- Asambodo:

-

ISO 9001, OA

- Akwụkwọ ikike:

-

Afọ 1

- Emechara ahịa na-azụ ahịa:

-

Ndị injinia dị maka igwe ọrụ na mba ofesi

- Aha aha:

-

tomato mado mmepụta ahịrị

- Ihe:

-

304 Igwe anaghị agba nchara

- Aha:

-

akara akara tomato

- Ọrụ:

-

Psa Pulping ịta Sterilaiz ndochi

- Ikike:

-

3 tọn / h tomato ọhụrụ nwere ike ịmepụta mpempe tomato 500kg

- Ojiji:

-

Industrial tomato mado nhazi osisi

- Ngwa:

-

chilli ihendori, aprịkọt jam Ndinam igwe

- Steam Kpo oku:

-

Ee na ji esi mmiri ọkụ

- Nkebi:

-

Automatic zuru ezu tomato tapawa mmepụta akara

- Njirimara:

-

otu nkwụsị ọrụ

- 3 Set / Sets per Month tomato mado mmepụta akara

- Nkwakọ ngwaahịa nkọwa

- 1.Stable osisi ngwugwu echebe igwe si iku na mmebi. 2.Wound plastic film na-eme igwe nke keguru mmiri na corrosion.3.Fumigation-free ngwugwu na-enyere ndị ezigbo omenala nwechapụ. 4.The nnukwu size igwe ga-ofu ke akpa na-enweghị ngwugwu.

- Port

- Shnaghai

- Etiti oge :

- 60 -90 ụbọchị

2.Tmiri ihe ọ pasteụ tomatoụ niile na-emepụta ahịhịa:

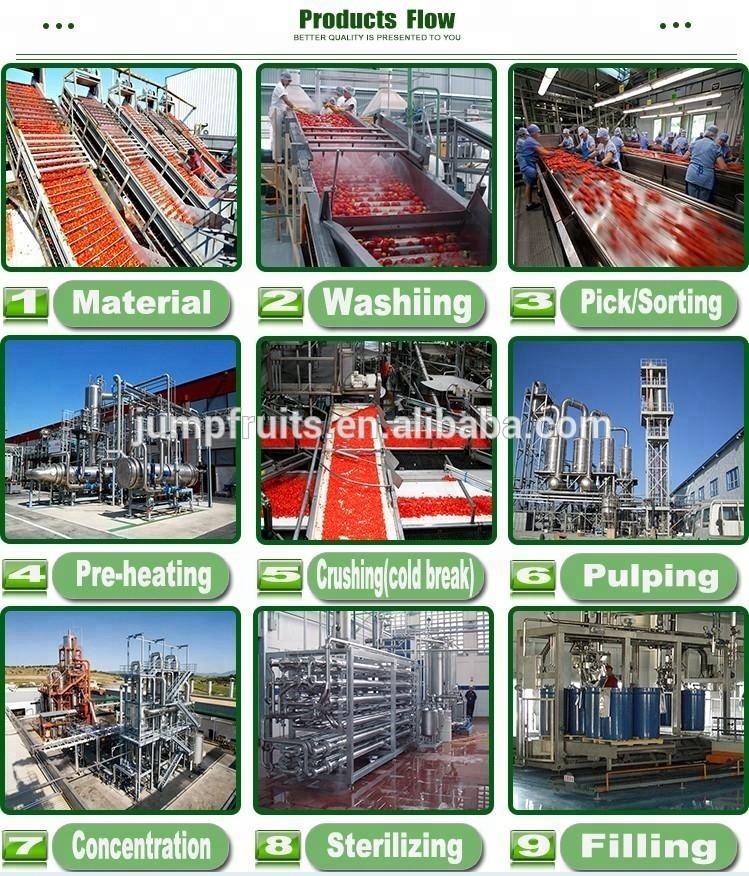

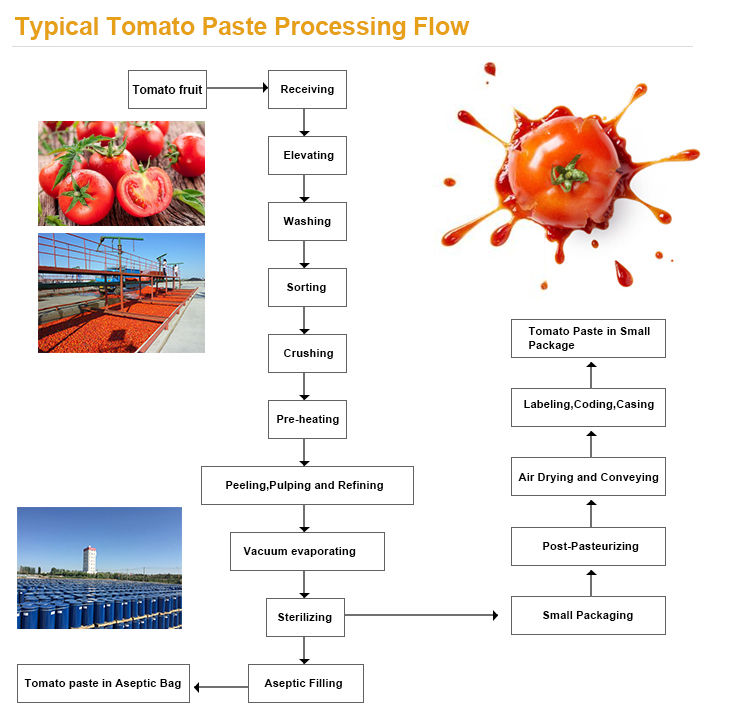

A: sistemụ nkwalite nke mkpụrụ mbụ, sistemụ nhicha, sistemụ idozi, sistemụ ndozi, sistemụ sterilization tupu kpụ ọkụkụ, sistemụ pulping, agụụ ịta ahụhụ usoro, sterilaization system, aseptic bag filling system

B: mgbapụta → na-agwakọta drum → homogenization → deaerating → nwoke ịga ụlọ ọgwụ → igwe na-ejuputa igwe pping capping igwe → ọwara spray sterilizer → draya → nzuzo → ịkụ ọkpọ

3. Ikpeazụ ngwaahịa ịta: Brix 28-30%, 30-32% oyi gbajiri na agbajiri agbaji, 36-38%

Igwe akwa FreshTomato

A na-asacha Tomato site na mmiri dị elu na igwe ịsa ahụ. Igwe nchacha ahịhịa na-ebute tomato ehichapụrụ na usoro ọzọ.

Ọhụrụ igwe ala sorting igwe

Mkpụrụ osisi a kpochara abanye n'ime igwe site na nri nri, ma na-atụgharị n'ihu na ntaneti. Ndị ọrụ na-ahọrọ tomato erughị eru iji hụ na ogo nke ngwaahịa ikpeazụ.

Tomato Agbaji mgbapụta

Ejiri maka ibuga ma gwerie tomatos, na-akwadebe maka ikpo ọkụ na ịpịpịa.

Tomato tubular Preheater

Tubular preheater na-eme ka okpomoku dị ọkụ site na ikpo ọkụ uzuoku, nke mere na iji mee ka pulp dị nro ma gbanyụọ enzymes ahụ.

Tomato Single-ọwa Pulping Machine

A na-eji igwe na-eme ihe eji eme otu ihe maka nkewa nke pulp na ihe fọdụrụ site na tomato anuahade na preheated. Ihe site na usoro ikpeazụ na-abanye n'ime igwe site na ntinye nri, na gburugburu gburugburu na-esi na ntanetị tinyere cylinder ahụ. Site na ike nke centrifugal, a na-akụ ihe ahụ. A na-esi na pulp gafere site na sieve ma zigara ya na usoro ọzọ, ebe akpụkpọ ahụ na mkpụrụ na-agbapụta site na nkwụsị fọdụrụ, na-emezu ebumnuche nkewapụ akpaka Enwere ike ịgbanwe ọsọ ọsọ site na ịgbanwe sieve na ịkpụzi ụzọ ntụgharị nke ihe nchacha ahụ.

Tomato uche agụụ Evaporator

A na-eji akụrụngwa a eme ihe maka agụụ agụụ nke tomato pulp n'okpuru obere okpomọkụ. Steam na-eri nri n'ime jaket na akụkụ ala nke ji esi mmiri ọkụ, na-eme ihe dị n'okpuru agụụ obụpde na ikusi. Blender na esi mmiri ọkụ na-enyere aka ike nke ihe.

Tomato tapawa tuber sterilizer

Tubular sterilizer na-eme ka ọnọdụ okpomọkụ nke uche dị elu site na ikpo ọkụ uzuoku, na-emezu ebumnuche nke ụlọ ọgwụ.

CIP ọcha usoro

Ọkara akpaka ihicha usoro

Gụnyere acid tank, isi tank, mmiri ọkụ, mmiri mgbanwe usoro yana njikwaystems. Na-ehicha ahịrị niile.

Tomato tapawa ejuputa akara na igwe nkwakọ ngwaahịa

Kwesịrị ekwesị maka mpempe akwụkwọ tomato, mango puree na ngwaahịa viscous ndị ọzọ.

Ngwaahịa edemede

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu