Mkpọ tin tomato mado nhazi osisi / mkpụrụ osisi juicer mmepụta akara

- Nọmba nlereanya:

-

Ugbokodo

- Brand aha:

-

SH-JUMP

- Ebe Mmalite:

-

Shanghai, China

- Voltaji:

-

380V

- Ike:

-

4kw

- Dimension (L * W * H):

-

1100 * 265 * 920mm

- Arọ:

-

100T

- Asambodo:

-

OA ISO

- Akwụkwọ ikike:

-

12 Ọnwa ole na

- Emechara ahịa na-azụ ahịa:

-

Ndị injinia dị maka igwe ọrụ na mba ofesi

- Ọnọdụ:

-

Ọhụrụ

- Ụdị:

-

uzo isi nhazi akara

- Aha aha:

-

oroma mkpụrụ nhazi akara

- Production ikike:

-

0.5-500T / H

- Ikike:

-

1-5t / h

- Ihe:

-

NZO304

- Akụrụngwa:

-

Mkpụrụ osisi ọhụrụ

- Advantage:

-

Ogologo oge mgbe ire ahịa gasịrị

- Ngwa:

-

Mkpụrụ

- Agba:

-

Ihe ndị ahịa chọrọ

- Ọrụ:

-

Usoro nhazi niile

- Ojiji:

-

nhazi ihe ọ juiceụ juiceụ

- 8 Set / Setịpụrụ kwa ọnwa akara mkpụrụ osisi oroma

- Nkwakọ ngwaahịa nkọwa

- ọkọlọtọ mbupụ ngwugwu, ọbọp site plastic ịse na osisi ikpe

- Port

- Shanghai

- Etiti oge :

- 60-90days

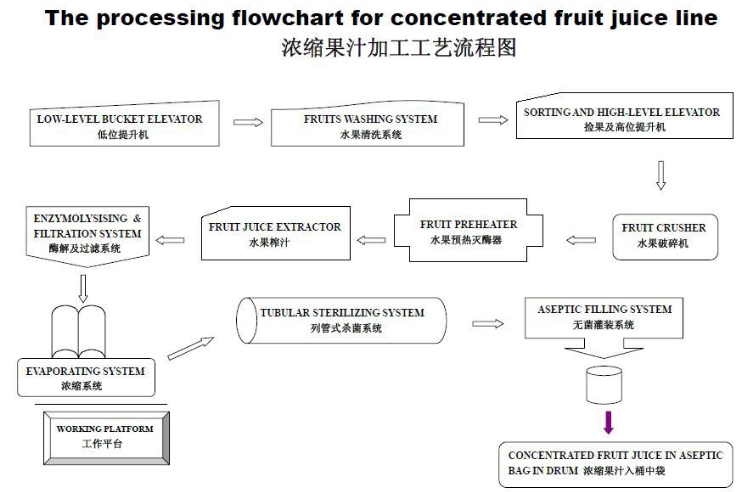

2.Usoro ihe nile:

A: sistemụ nkwalite nke mkpụrụ mbụ, sistemụ nhicha, sistemụ idozi, sistemụ kpochapu, sistemụ sterilization tupu kpụ ọkụkụ, sistemụ pulping, agụụ ịta ahụhụ usoro, sterilaization system, aseptic ndochi system

B: mgbapụta → na-agwakọta drum → homogenization → deaerating → nwoke ịga ụlọ ọgwụ → igwe na-ejuputa igwe pping capping igwe → ọwara spray sterilizer → draya → nzuzo → ịkụ ọkpọ

Cleaninggba nhicha igwe

Main njirimara:

1 Eji ya asa tomato, strawberry, mango, wdg.

2 Pụrụ iche imewe nke sọọfụ na afụ iji hụ a site nhicha na-ebelata mmebi nke mkpụrụ osisi dị ka mma.

3 Adabara ọtụtụ ụdị mkpụrụ osisi ma ọ bụ akwụkwọ nri, dị ka tomato, strawberry, apụl, mango, wdg.

Ike Ike: 3KW

homogenizer

Etinyere nụchaa ma ọ bụ emulsification ihe ọ juiceụ juiceụ, jam, onunu.

Na ugboro akakabarede akara na centralized akara kabinet

Ngosipụta njikwa ikike 1T / H.

CIP ọcha usoro

Ọkara akpaka ihicha usoro

Gụnyere acid tank, isi tank, mmiri ọkụ, mmiri mgbanwe usoro yana njikwaystems. Na-ehicha ahịrị niile.

Ike : 7.5KW

Citrus wepụ

Main njirimara:

1. Igwe anaghị agba nchara ewu na niile na kọntaktị na-ebupụta, a kpam kpam nchọ igwe anaghị agba nchara ewu na niile kọntaktị na-ebupụta, a kpam kpam nchọ igwe anaghị agba nchara piping usoro ibufe ihe ọ systemụ toụ na igwe anaghị agba nchara finishers.

2. Citrus mmịpụta usoro bụ ihe pụrụ iche na nke na-eweghachi mmanụ n'otu oge yana ihe ọ juiceụ juiceụ n'otu oge usoro mmịpụta ahụ.

3. A na-ekewapụta ihe ndị na-eme ihe ilu dị ka cores, membranes, seed, wdg, site na pre-finisher tube site na ihe ọ juiceụ juiceụ na ihe ọ juiceụ juiceụ mkpụrụ osisi mkpụrụ ndụ mkpụrụ mmiri na mkpụrụ mmiri mkpụrụ osisi ozugbo.

4. Nke a pụtara ìhè arụmọrụ ka ekwe omume n'ihi na ike nke Citrus Extractor afanyekwa citrus mkpụrụ rụọ ọrụ nke ọma na dịgasị iche iche nke nke na udi.

5. Jikwaa ọtụtụ ụdị citrus n’ụwa na nha. Nke a na - ebelata ọnụọgụ ndị na - ewepụta ihe ndị achọrọ, na - ebute nchekwa ego na belata ngwa ọrụ.

6. A na-ebelata ojiji nke mmiri na mkpofu ahihia site n'iji usoro mmeghari mmiri.

Họrọ igwe anaghị agba nchara mgbodo, nri-ọkwa na ike plastic ma ọ bụ igwe anaghị agba nchara scraper, smoothing agụba ije iji gbochie mkpụrụ jam; Iji mbata mgbochi-corrosion biarin, abụọ-kwadoro akara; ya na igwe ntụgharị nnyefe na-agbanwe agbanwe, agbanwe agbanwe Speedgba ọsọ na ọnụ ala ịrụ ọrụ Isi okwu na-aga ebe a.

Igwe anaghị agba nchara ala ebu, adiana na ngwọta, a full nso nke ego, dịghị mkpa nsọtụ. Ihe eji eme ihe nkpuru osisi, esere ese ihe eji eme ka carbon, ihe nchara antiskid pal, igwe anaghị agba nchara.

C. Ogha

Fusing Italian technology, multiple tent nke cross-agụba Ọdịdị, crusher size nwere ike gbanwee dị ka ndị ahịa ma ọ bụ ụfọdụ oru ngo chọrọ, ọ ga-eme ka ihe ọ juiceụ juiceụ ihe ọ juiceụ juiceụ ihe ọ rateụ ofụ nke 2-3% ikwu na omenala Ọdịdị, nke bụ adabara mmepụta nke yabasị ihendori, karọt ihendori, ose ihendori, apụl ihendori na mkpụrụ osisi na akwụkwọ nri ndị ọzọ na ngwaahịa

D. Ugboro abụọ-ogbo pulping igwe

Ọ tapered ntupu Ọdịdị na ọdịiche na ibu nwere ike gbanwee, ugboro akara, nke mere na ihe ọ juiceụ juiceụ ga-ọcha; Esịtidem ntupu aperture dabeere na ndị ahịa ma ọ bụ ụfọdụ oru ngo chọrọ ịtụ

E. Onye nkesa

Single-mmetụta, abụọ-mmetụta, Mmaji-mmetụta na multi-mmetụta evaporator, nke ga-azọpụta ndị ọzọ ume; N'okpuru agụụ, na-aga n'ihu obere okpomọkụ okirikiri kpo oku jirichaa nchedo nke nri na ihe onwunwe dị ka ndị mbụ. Enwere sistemu mgbake uzuoku na okpukpu abuo nke condensate, o nwere ike belata oriri uzuoku;

F. nwoke ịga ụlọ ọgwụ

Inwe nwetara itoolu patented technology, na-zuru uru nke ihe onwunwe onwe okpomọkụ mgbanwe ịzọpụta ume- banyere 40%

F. Igwe na-ejuputa

Nabata teknụzụ Italiantali, isi na isi abụọ, na-aga n'ihu na-ejuputa, belata nloghachi; Iji uzuoku ọgwụ na sterilaiz, iji hụ na ejuputa na ọnọdụ aseptic, ndụ ndụ nke ngwaahịa ga-twp afọ na ụlọ okpomọkụ; Na ndochi usoro, iji turntable eweli mode zere abụọ mmetọ.

Ngwaahịa edemede

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu