bluuberi jam mmepụta akara na asọmpi ego

- Ọnọdụ:

-

Ọhụrụ

- Ebe Mmalite:

-

Shanghai, China

- Brand aha:

-

OEM / JUMPFRUITS

- Nọmba nlereanya:

-

JPF-GJL003

- Ụdị:

-

bluuberi jam mmepụta akara

- Voltaji:

-

220V / 380V

- Ike:

-

5.5kw

- Arọ:

-

Iri 60

- Dimension (L * W * H):

-

1720 * 1160 * 1280mm

- Asambodo:

-

OA asambodo

- Akwụkwọ ikike:

-

Ọnwa 12, Afọ 1

- Emechara ahịa na-azụ ahịa:

-

Ndị injinia dị maka igwe ọrụ na mba ofesi

- Aha aha:

-

bluuberi jam mmepụta akara

- Ihe:

-

Igwe anaghị agba nchara 304 nri ọkwa

- Ojiji:

-

Ejiji eji

- Ikike:

-

10-500 T / D

- Njirimara:

-

Tụgharịa Igodo

- Ngwa:

-

Nri nri

- Nkebi:

-

Industrial Mkpụrụ puree Ndinam igwe

- Aha:

-

Mkpụrụ puree Ndinam igwe

- Agba:

-

Ihe ndị ahịa chọrọ

- 10 Set / Setịpụrụ kwa ọnwa Strawberry jam mmepụta akara

- Nkwakọ ngwaahịa nkọwa

- 1.Stable osisi ngwugwu echebe igwe si iku na mmebi. 2.Wound plastic film na-eme igwe nke keguru mmiri na corrosion.3.Fumigation-free ngwugwu na-enyere ndị ezigbo omenala nwechapụ. 4.The nnukwu size igwe ga-ofu ke akpa na-enweghị ngwugwu.

- Port

- Shanghai

- Etiti oge :

- wihin ọnwa 3

2.Usoro ihe nile:

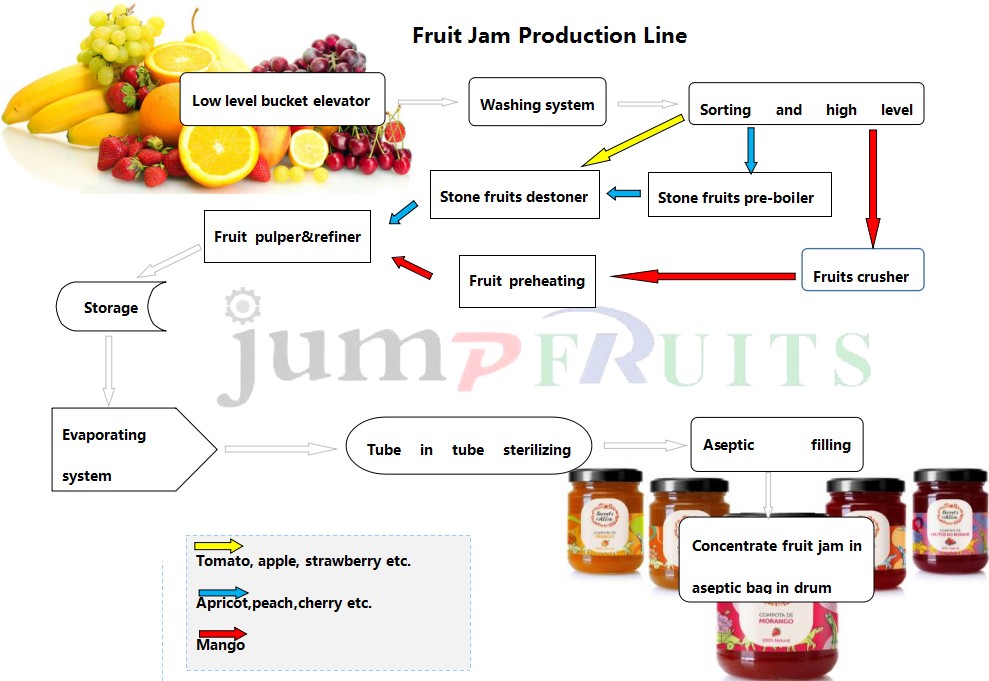

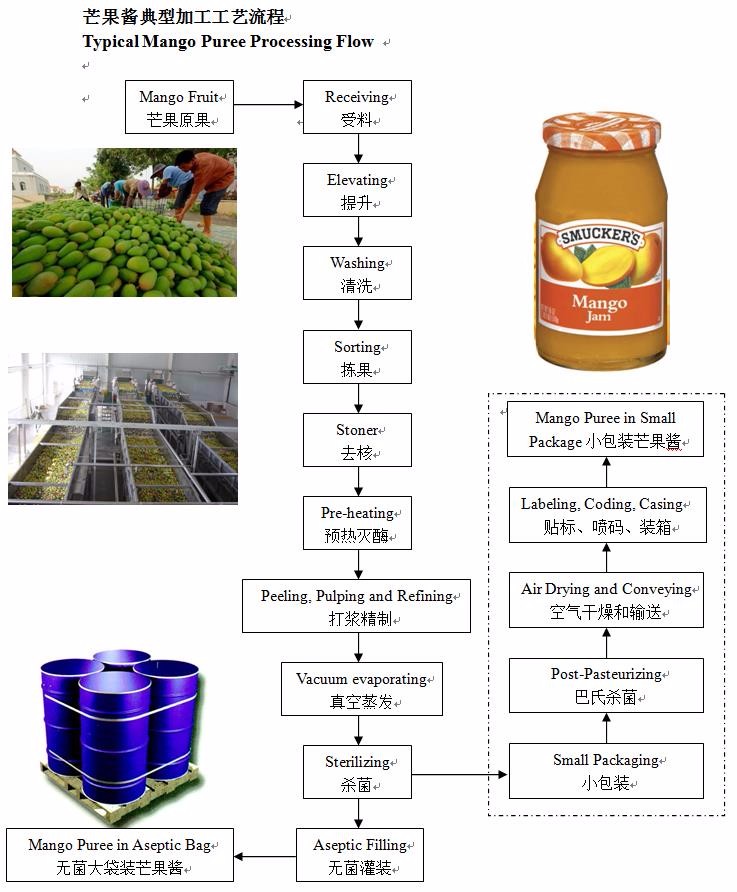

A: sistemụ nkwalite nke mkpụrụ mbụ, sistemụ nhicha, sistemụ idozi, sistemụ ndozi, sistemụ sterilization tupu kpụ ọkụkụ, sistemụ pulping, agụụ ịta ahụhụ usoro, sterilaization system, aseptic bag filling system

B: mgbapụta → na-agwakọta drum → homogenization → deaerating → nwoke ịga ụlọ ọgwụ → igwe na-ejuputa igwe pping capping igwe → ọwara spray sterilizer → draya → nzuzo → ịkụ ọkpọ

Uru anyị:

1.Turnkey ngwọta. Ọ dịghị mkpa ichegbu onwe gị ma ọ bụrụ na ịmachaghị otu esi arụ osisi na mba gị, ọ bụghị naanị na ị ga-enye gị akụrụngwa ahụ, kamakwa ị ga-enye ndị ọrụ nkwụsị, site na ụlọ nkwakọba ihe gị (mmiri, ọkụ eletrik, ndị ọrụ), ọzụzụ ndị ọrụ, ntinye igwe na nbibi, ọrụ ogologo oge mgbe ire ere wdg.

2.15 afọ mbupụ ahụmahụ, na-ebufe ibu n'ọnụ ụzọ gị ngwa ngwa

Ọrụ 3.customized, anyị ga-anwa ike anyị niile iji nweta ihe ị chọrọ.

4.kwado nkwa: 12 ọnwa. Mgbe nke ahụ gasị, ndị injinia na-ejikwa ego njem gị na ihe ndị ọzọ na-akwụ ụgwọ. Anyị na-enye ọrụ ogologo oge ire ahịa.

Isi uru nke usoro sistemụ anyị:

1. High mmepụta ọsọ nweta site ọhụrụ e mere isi usoro (otu isi ma ọ bụ ejima isi dị), mma pụrụ ịdabere na a n'ụzọ zuru ezu PLC achịkwa onwe diagnostic arụmọrụ mode.

2. Ukwuu otutu site nzute iche iche mbukota ụkpụrụ dị iche iche na ngwaahịa.

3 Na-ejikọta nke ọma na ọkpọkọ ọkpọ ọkpọ ọkpọ, ma ọ bụrụ na ụfọdụ adịghị arụ ọrụ na nzacha ahụ, ngwaahịa a ga-alaghachi azụ n'ime nchekwa nchekwa tupu UHT sterilizer

4. Iji hermetically mechie akpa akpa ana achi achi akpa ga-anọgide na-akpali mmasị tupu ọ jupụta.

5. A na-eji uzu mmiri jupụtara na mmiri zuru ezu maka ịgba ọgwụ mgbochi nke ndozi, okpu na akụkụ ekpughere nke filler tupu ntụgharị ọ bụla. ADGH C CHEMICALS.

6. Theka akara nke valvụ jupụta n'ime ime ahụ na-eme ka ngwaahịa kwụsị kpamkpam na mpaghara ngwugwu ngwugwu.

7. The hermetic okpomọkụ akara nke ndozi na-enye a tamper doro anya mmechi na a elu oxygen mgbochi.

8. Nzube aseptic design nke filler na-enye ohere n’enweghi nsogbu. Ọrụ n'ime oge tomato / mkpụrụ osisi zuru oke, na-eme ka arụmọrụ gị dịkwuo elu

9. CIP na SIP dị yana tube na tube sterilizer

Ọrụ Nkwalite Ndị Ahịa

* Ajụjụ na ndụmọdụ nkwado.

* Nlele nlele nlele.

* Lelee Factlọ Ọrụ Anyị.

Mgbe-Sales Service

* Ọzụzụ otu esi etinye igwe, ọzụzụ etu esi eji igwe.

* Ndị injinia dị maka igwe ọrụ na mba ofesi.

Nkwakọ ngwaahịa nkọwa: mbupụ ọkọlọtọ

Nzipu Ihe: n'ime 90 ụbọchị ma ọ bụ kwa ahịa na-arịọ

ihe ọ beụ beụ na-aba n'anya

91.8% Nzaghachi Rate

tomato mado mmepụta ahịrị

91.8% Nzaghachi Rate

Ngwaahịa edemede

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu