Ngwa igwe ero mkpọ akpaaka

- Ọnọdụ:

- Ọhụrụ

- Ebe amụrụ:

- Shanghai, China

- Aha ika:

- JUMPFRUITS

- Nọmba nlereanya:

- JPF-MG001

- Ụdị:

- AHỤRỤ Nhazi

- Voltaji:

- 220V/380V

- Ike:

- 3kw

- Arọ:

- 80 TON

- Akụkụ (L*W*H):

- 1380*1200*2000mm

- Asambodo:

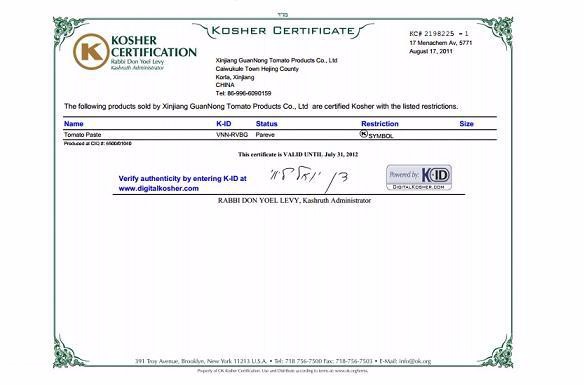

- ISO 9001, CE

- Akwụkwọ ikike:

- 1 Afọ

- Enyere ọrụ ere-ahịa mgbe:

- Ndị injinia dị maka igwe ọrụ na mba ofesi

- Aha ngwaahịa:

- Ngwa igwe ero mkpọ akpaaka

- Ọrụ:

- Na-ewepụta

- Ngwa:

- Osisi piich mkpọ

- Ojiji:

- Igwe mmepụta ihe

- Ike:

- 2000-5000kg / h

- Ihe:

- Igwe na-edozi akwụkwọ nri mkpụrụ osisi akpaaka

- Agba:

- Ihe isi awọ Silver ma ọ bụ ihe ndị ahịa chọrọ

- Ihe:

- 304 igwe anaghị agba nchara

- Njirimara:

- Tụgharịa igodo Project

- Aha:

- Ngwa igwe ero mkpọ akpaaka

- Ikike inye:

- 20 Tọọ/Setịpụ kwa ọnwa akpaka igwe ero ero mkpọ

- Nkọwa nkwakọ ngwaahịa

- 1.Stable osisi ngwugwu na-echebe igwe site na iku na mmebi.Ihe nkiri plastik 2.Wound na-eme ka igwe ghara ịdị na mmiri na corrosion.3.Fumigation-free ngwugwu na-enyere ndị na-eji ire ụtọ ekpochapụ.4.The nnukwu size igwe ga-edozi na akpa na-enweghị ngwugwu.

- Port

- Shanghai, China

- Etiti oge:

- Ụbọchị 60

Okwu mmeghe nke ahịrị niile:

Ahịrị mmepụta ahụ bụ igwe na-asa akwa, igwe mbuli elu, igwe na-enyocha, tank enzymolysis, decanter, ultrafilter, homogenizer, igwe degassing, igwe sterilization, igwe na-ejuputa, igwe ọkọlọtọ na akụrụngwa akụrụngwa ndị ọzọ.Emebere ahịrị mmepụta a na echiche dị elu na ogo akpaaka dị elu;Isi akụrụngwa bụ ihe niile ejiri igwe anaghị agba nchara dị elu, nke na-emezu ihe achọrọ ịdị ọcha nke nhazi nri.

Nhọrọ ihe eji eme ihe → Ọgwụgwọ tupu → Canning → Mkpuchi mkpochapụ → Mgbochi na oyi → Nnyocha mkpuchi → Nchekwa ngwugwu

Akụrụngwa nke mkpụrụ osisi na akwụkwọ nri n'ozuzu nwere ihe ndị a:

Ome achara, olu, ose, ketchup, kukumba, radishes, agwa ndụ ndụ, apụl, pears, citrus, piich, cherị, painiapulu, wdg.

Nkwakọ ngwaahịa:karama iko, PET plastic karama, Mkpọ, aseptic mgbanwe nkwakọ, ụlọ akpa, 2L-220L aseptic akpa, katọn nkwakọ, plastic akpa, 70-4500g tin Mkpọ.

Igwe na-afụ ikuku & ịsa ahụ

1 A na-eji saa tomato ọhụrụ, strawberry, mango, wdg.

2 Pụrụ iche imewe nke sọọfụ na bubbling iji hụ na a site ihicha na ibelata mmebi nke mkpụrụ osisi ahụ.

3 Kwesịrị ekwesị maka ọtụtụ ụdị mkpụrụ osisi ma ọ bụ akwụkwọ nri, dị ka tomato, strawberry, apple, mango, wdg.

Igwe ndochi

1.Adopt nkà na ụzụ Ịtali, isi-isi na isi abụọ, na-ejuputa na-aga n'ihu, belata nloghachi;

2.Using uzuoku injection ka sterilaiz, iji hụ na ejuputa na aseptic steeti, ndụ shelf nke ngwaahịa ga-twp afọ na ụlọ okpomọkụ;N'ime usoro njuputa,

3.Iji turntable ebuli mode zere nke abụọ mmetọ.

1. Ngwa ngwa oghe oghe, mgbochi nchekwa.

2. Na ọkpọkọ ikuku abịakọrọ ka ọ dị mma maka nhazi nrụgide nke ndị ahịa.

3.Tọ nnukwu efere shei nwere mkpuchi mkpuchi oyi akwa, nke nwere ike ibelata ike oriri.

4. Control System-- Touch screen + PLC ọ na-akpaghị aka na-emezu dum usoro nke ike ọgwụgwụ, kpo oku, jụrụ nke counter mgbali na drainage.

Ọkụ na tube sterilizer

1. The united bụ nke ngwaahịa na-enweta tank, superheated mmiri tank, nfuli, ngwaahịa dual filter, tubular superheated mmiri n'ịwa usoro, tube na tube okpomọkụ Exchanger, PLC akara usoro, Control kabinet, uzuoku ntinye usoro, valves na sensọ, wdg.

2. Incorporated Italian technology na kwekọrọ na Euro-ọkọlọtọ

3. Nnukwu ebe mgbanwe okpomọkụ, obere ike oriri na nlekọta dị mfe

4. Were mirror ịgbado ọkụ tech na-eji ire ụtọ anwụrụ nkwonkwo

5. Backtrack akpaaka ma ọ bụrụ na ezughi oke igba ogwu

6. CIP na auto SIP dị ọnụ na aseptic filler

7. Liquid larịị na temp akara na ozugbo

A. Ekenyere maka asambodo nyocha akụrụngwa na akwụkwọ ntuziaka, iji hụ na ndị ọrụ wụnye ma jiri ya nke ọma

B.Equipment iji ruo ebe a na-aga, ụlọ ọrụ ahụ ga-eziga ndị injinia na-eduzi ntinye na nhazi na ọzụzụ ndị ahịa ruo mgbe afọ ojuju.

C.The akwụkwọ ikike oge ga-free ndị ahịa na-eyi ngwa, shelf ndụ n'èzí nke m ụlọ ọrụ na-enye akụkụ na-eri.

D. M na-enye ọrụ nlekọta ogologo ndụ, gụnyere ma ọ bụrụ na ọ dị mkpa, iziga ndị injinia na ndị ahịa na ọrụ ahụ.

1.Professional aku na dum osisi ngwá imewe, n'ichepụta, R & D na turnkey oru ngo maka Mkpụrụ & akwụkwọ nri miri nhazi, ihe ọṅụṅụ Processing na Dairy Processing.

2.over afọ iri anọ 'ọgaranya ahụmahụ na ụda oru ike.

3.ihe karịrị 110 guzosie ike mkpụrụ osisi na akwukwo nri ahịrị mmepụta.

4.Has guzosie ike ike oru imekọ ihe ọnụ na Italy FBR, Ing.Rossi, Bertuzzi CFT.

5.We nwere ike inye dum mmepụta ahịrị nhazi 20-1500 tọn raw mkpụrụ kwa ụbọchị dị ka ndị ahịa.

6.ngwaahịa na-abanyekwa n'ahịa mba ofesi.

Ahụmịhe mbupụ afọ 7.15, buru ibu ngwa ngwa n'ọnụ ụzọ gị

8.customerized ọrụ, degharịa anyị ngwaahịa ma ọ bụ OEM maka gị chọrọ